Research overview:

My research focuses on the design and development of sustainable composite material systems, integrating materials science, mechanics-informed modelling, and data-driven approaches to enable circularity, durability, and high performance. The overarching aim is to engineer lightweight and multifunctional composite materials in which recyclability, repairability, and lifetime performance are embedded directly into material architecture rather than assessed retrospectively.

My research is structured around three tightly integrated themes:

- Circular and multifunctional composite materials, encompassing the development of recyclable and self-healing polymer matrices and coatings, bio-based fibre-reinforced composite systems, and multifunctional structural materials that combine load-bearing capability with additional functions such as energy storage, sensing, or adaptive response.

- Materials-informed mechanics and multiscale modelling, establishing predictive frameworks that link microstructural damage mechanisms, durability, and processing conditions to structural-scale performance and lifetime, enabling damage-tolerant and resource-efficient composite design.

- Data-driven materials design for sustainability-by-design, integrating physics-based modelling with artificial intelligence to accelerate materials discovery and optimisation, and to systematically explore trade-offs between mechanical performance, manufacturability, life-cycle assessment, and environmental impact, particularly under sparse and noisy data conditions.

Mechanics of Composites

Advanced Computational Models

Architected Cellular Materials

Shape-morphing composites

Energy-storage materials

Data-driven methods

Research highlights:

(1) Data-driven materials design for sustainability-by-design

Designing sustainable composite materials requires balancing mechanical performance with durability, repairability, and environmental impact across a high-dimensional design space encompassing resin chemistry, reinforcement architecture, processing parameters, and service conditions. Conventional trial-and-error approaches based on iterative experiments or high-fidelity simulations are time- and resource-intensive, limiting their ability to guide sustainability-by-design. Although data-driven methods are increasingly adopted, many rely on large datasets and neglect underlying physical principles, reducing their robustness for predictive materials engineering.

I have developed original data-driven methodologies to accelerate composite materials design and optimisation:

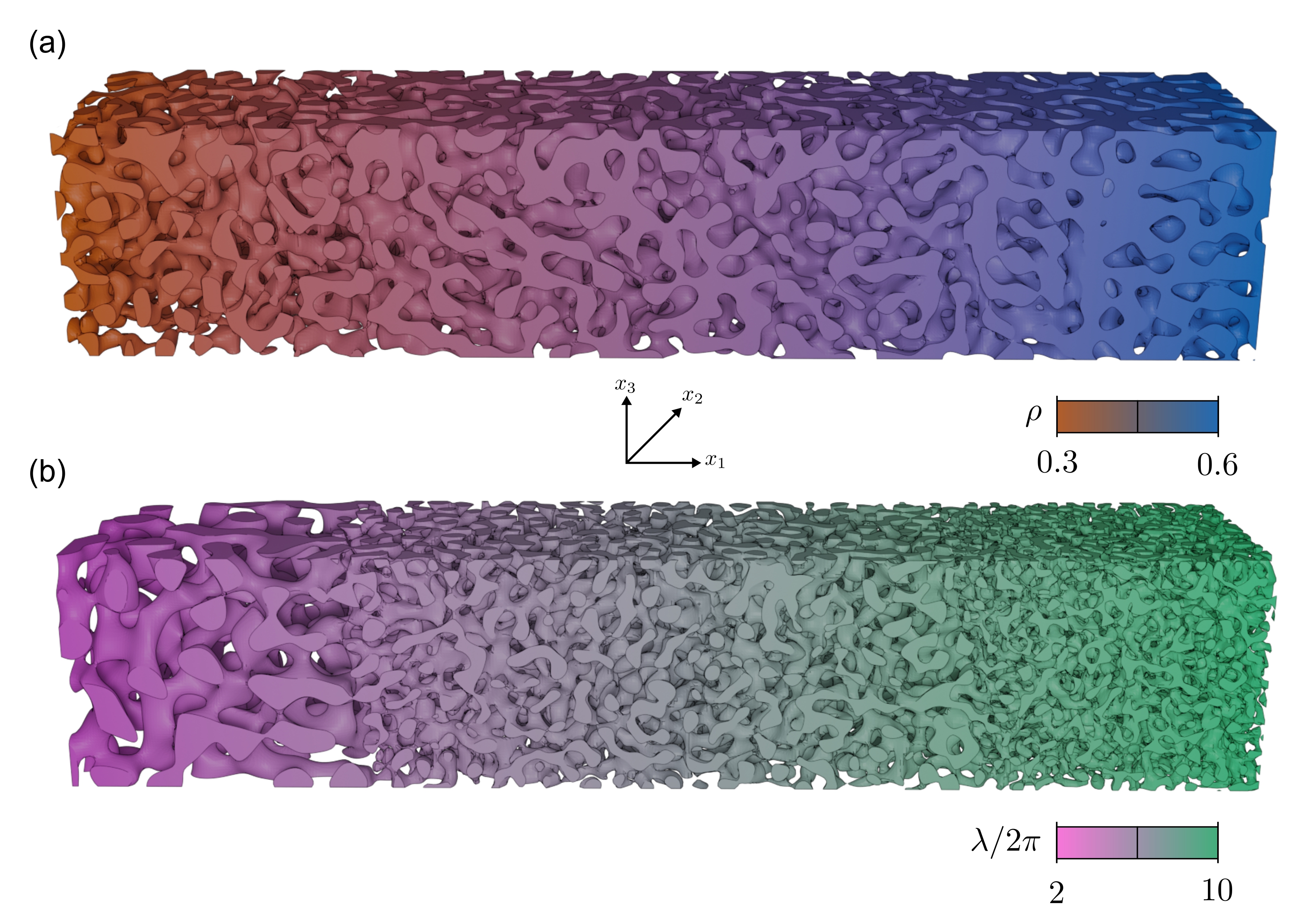

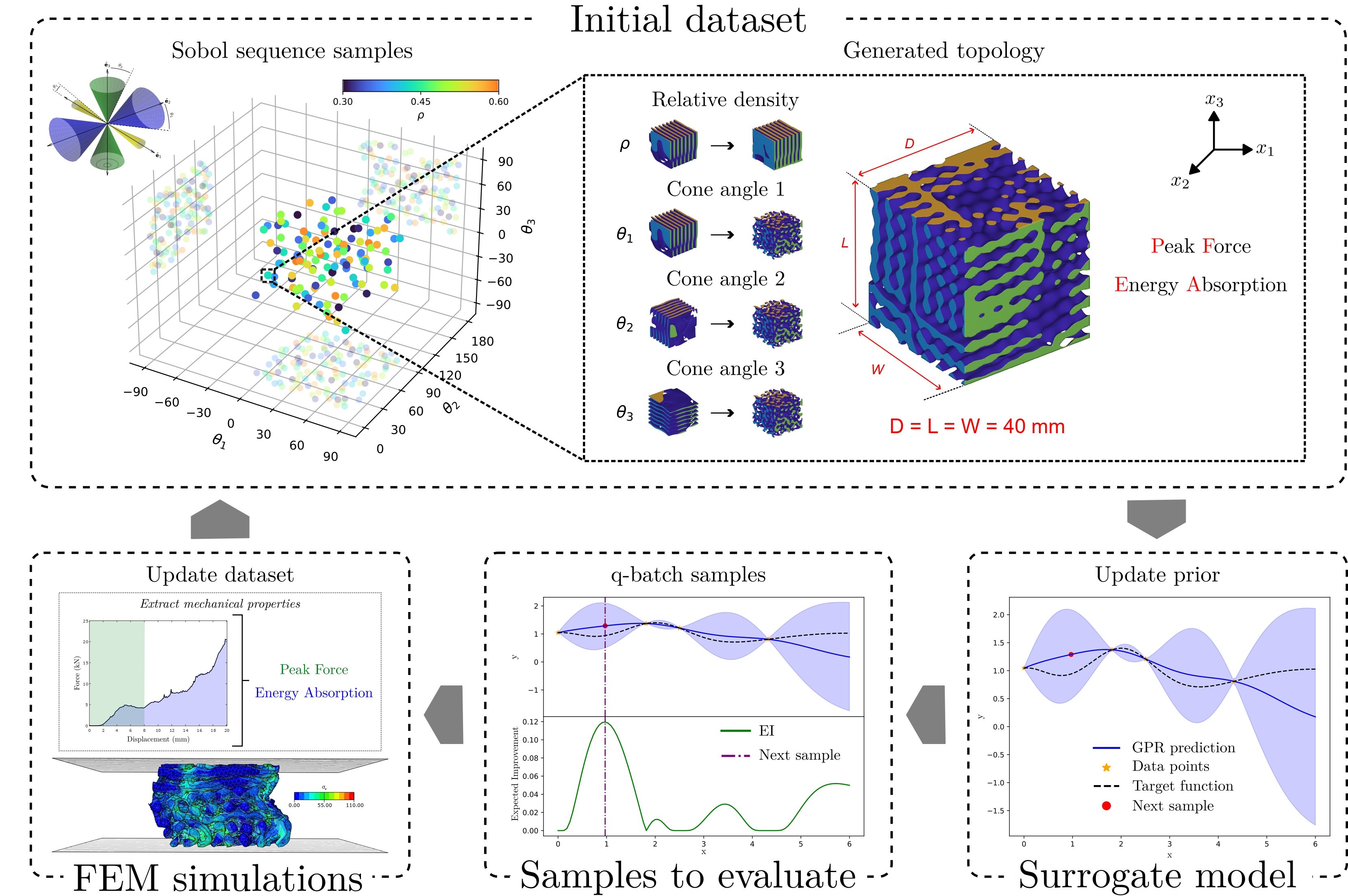

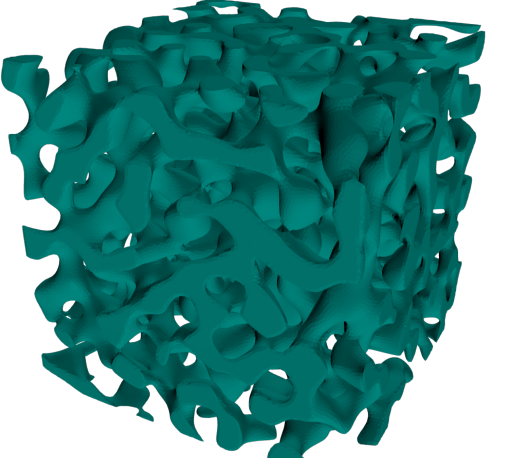

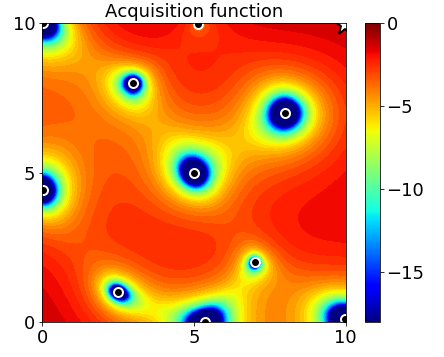

- Bayesian Surrogate Modelling: Developed multi-objective and multi-fidelity Bayesian surrogate models for handling sparse, noisy datasets to optimise non-linear crushing and energy absorption behaviour of architected composites, cutting the computational cost of topology optimisation by orders of magnitude.

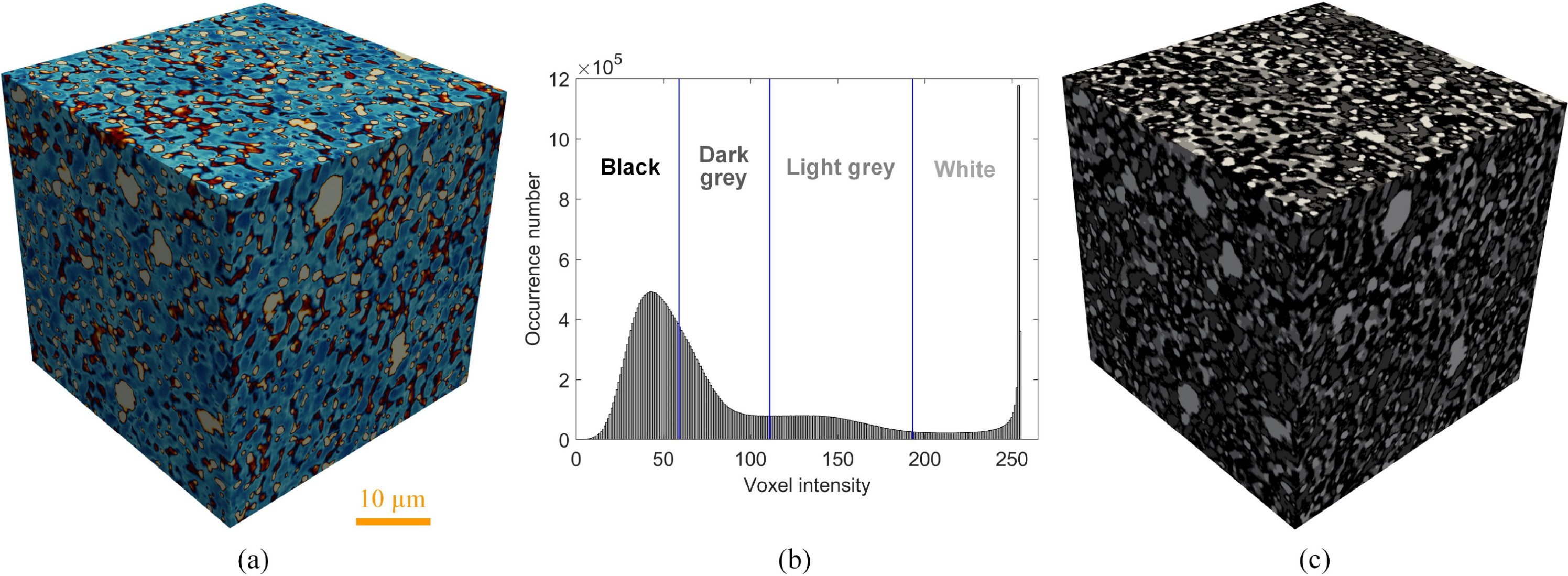

- Microstructure–Property Mapping: Created a statistics-encoded neural network that learns microstructure–property relationships while embedding micromechanical constraints, enabling fast screening of candidate architectures with physical consistency.

- Physics-Guided Inverse Design: Implemented a conditional generative adversarial network (cGAN) for solving multiphysics inverse-design problems, such as thermal–poro–mechanical optimisation, enabling the automatic generation of microstructures and process parameters that meet multiple performance targets simultaneously.

References:

[1] Kansara, H., Khosroshahi, S.F., Guo, L., Bessa, M.A. and Tan, W., Multi-objective Bayesian Optimisation of Spinodoid Cellular Structures for Crush Energy Absorption. Computer Methods for Applied Mechanics and Engineering, 2025. https://doi.org/10.1016/j.cma.2025.117890

[2] Fu, J. and Tan, W., 2025. Stochastic reconstruction of multiphase composite microstructures using statistics-encoded neural network for poro/micro-mechanical modelling. Computer Methods in Applied Mechanics and Engineering, 441, p.117986. https://doi.org/10.1016/j.cma.2025.117986

(2) Impact and crush behaviour of carbon fibre composites

Research summary:

Composite structures are susceptible to impact damage, which requires costly and highly inefficient experimental testing to meet safety-critical certification. My project aimed to develop a predictive material model for capturing impact damage and energy absorption capacity of CFRP.

1) A multiscale model was also proposed to take into account the physical mechanisms of deformation at different length scales of composite structures. This efficient strategy enables carrying out multiscale modelling from the properties of the constituents (fibre, matrix and interfaces) and homogenise the results into a constitutive model, followed by the transfer of information to the next length scale, which is both time-saving and economical for industry.

2) A physically-based model based on crystal plasticity has been proposed to accurately capture the inelastic behaviour and strain rate effect of composites subjected to shear or compressive or impact loading.

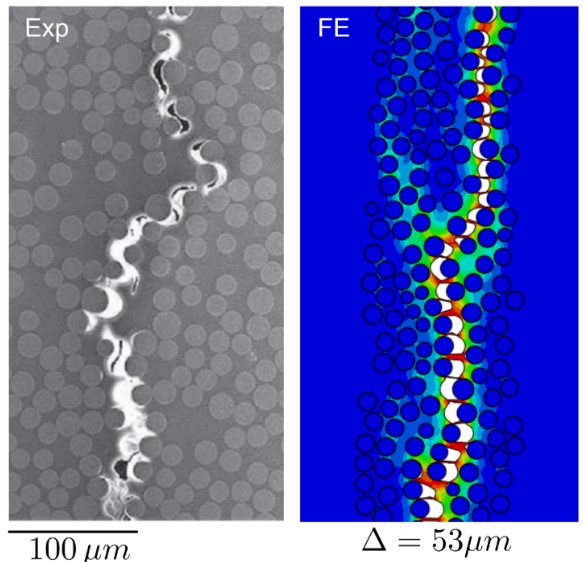

3) Low-velocity impact damage can drastically reduce the residual strength of a composite structure even when the damage is barely visible. The ability to computationally predict the extent of damage and compression-after-impact (CAI) strength of a composite structure can potentially lead to the exploration of a larger design space without incurring significant time and cost penalties. A high-fidelity three-dimensional composite damage model, to predict both low-velocity impact damage and CAI strength of composite laminates, has been developed and implemented as a user material subroutine in the commercial finite element package, ABAQUS/Explicit.

4) A crushing model based on a new distorted element deletion strategy was presented to capture the crushing behaviour of composite materials. This model solves the convergence issue due to element distortion under large deformation via deleting element based on the determinant of deformation gradient.

Reference papers:

- Au-Yeung K, Quintanas-Corominas A, Martínez-Pañeda E and Tan W (2023). Hygroscopic phase field fracture modelling of composite materials.Engineering With Computers, Springer DOI 10.1007/s00366-023-01820-z.

- Cheng ZQ, Tan W, Xiong JJ (2022). “Modelling Pre-fatigue, Low-velocity Impact and Post-impact Fatigue Behaviours of Composite Helicopter Tail Structures under Multipoint Coordinated Loading Spectrum.” Elsevier Thin-Walled Structures DOI10.1016/j.tws.2022.109349

- Wang X, Li P, Xiang D, Wang B, Zhang Z, Zhang J, Zhao C, Li H, Tan W, Wang J and Li Y (2022). “Influence of high-temperature, high-pressure, and acidic conditions on the structure and properties of high-performance organic fibers.” Materialpruefung/Materials Testing vol. 64 (5), 623-635. DOI10.1515/mt-2021-2099

- Tan W and Martínez-Pañeda E (2022). “Phase field fracture predictions of microscopic bridging behaviour of composite materials.” Elsevier Composite Structures vol. 286 DOI10.1016/j.compstruct.2022.115242

- Cheng, Z.Q., Xiong, J.J. and Tan W*, 2021. Fatigue Crack Growth and Life Prediction of 7075-T62 Aluminium-alloy Thin-sheets with Low-velocity Impact Damage under Block Spectrum Loading. International Journal of Fatigue, p.106618. https://doi.org/10.1016/j.ijfatigue.2021.106618.

- Cheng ZQ, Tan W and Xiong JJ (2021). “Progressive damage modelling and fatigue life prediction of Plain-weave composite laminates with Low-velocity impact damage.” Composite Structures vol. 273, DOI10.1016/j.compstruct.2021.114262

- Tan W and Martínez-Pañeda E (2020). “Phase field predictions of microscopic fracture and R-curve behaviour of fibre-reinforced composites.” Elsevier Bv Composites Science and Technology 108539-108539. DOI10.1016/j.compscitech.2020.108539

- Tan W and Liu B (2020). “A physically-based constitutive model for the shear-dominated response and strain rate effect of carbon fibre reinforced composites.”, Editors: Wang H. Elsevier Composites Part B: Engineering DOI10.1016/j.compositesb.2020.108032

- Tan W, Naya F, Yang L, Chang T, Falzon BG, Zhan L, Molina-Aldareguía JM, González C and Llorca J (2018). “The role of interfacial properties on the intralaminar and interlaminar damage behaviour of unidirectional composite laminates: Experimental characterization and multiscale modelling.” Composites Part B: Engineering vol. 138, 206-221. DOI10.1016/j.compositesb.2017.11.043

- Tan W and Falzon BG (2016). “Modelling the crush behaviour of thermoplastic composites.” Elsevier Composites Science and Technology vol. 134, 57-71. DOI10.1016/j.compscitech.2016.07.015

- Tan W, Falzon BG, Price M and Liu H (2016). “The role of material characterisation in the crush modelling of thermoplastic composite structures.” Composite Structures vol. 153, 914-927. DOI10.1016/j.compstruct.2016.07.011

- Tan W and Falzon BG (2016). “Modelling the nonlinear behaviour and fracture process of AS4/PEKK thermoplastic composite under shear loading.” Elsevier Composites Science and Technology vol. 126, 60-77. DOI10.1016/j.compscitech.2016.02.008

- Tan W, Falzon BG, Chiu LNS and Price M (2015). “Predicting low velocity impact damage and Compression-After-Impact (CAI) behaviour of composite laminates.” Composites Part a: Applied Science and Manufacturing vol. 71, 212-226. DOI10.1016/j.compositesa.2015.01.025

- Tan W, Falzon BG and Price M (2015). “Predicting the crushing behaviour of composite material using high-fidelity finite element modelling.” International Journal of Crashworthiness vol. 20, (1) 60-77. DOI10.1080/13588265.2014.972122

Example: Predicting the crushing process of thermoplastic composites

Example: High-velocity impact response of a carbon nanotube mat

(3) Mechanics of multifunctional materials and composites

Research summary:

We’ve successfully created a framework for inverse design and additive manufacturing of shape-morphing structures using functionally graded composites.

References:

- Kansara, H., Liu, M., He, Y. and Tan W, 2023. Inverse design and additive manufacturing of shape-morphing structures based on functionally graded composites. Journal of the Mechanics and Physics of Solids, 180, p.105382.

- Mao JJ, Wang S, Tan W and Liu M (2022). Modular multistable metamaterials with reprogrammable mechanical properties.ElsevierEngineering Structures vol. 272, DOI10.1016/j.engstruct.2022.114976

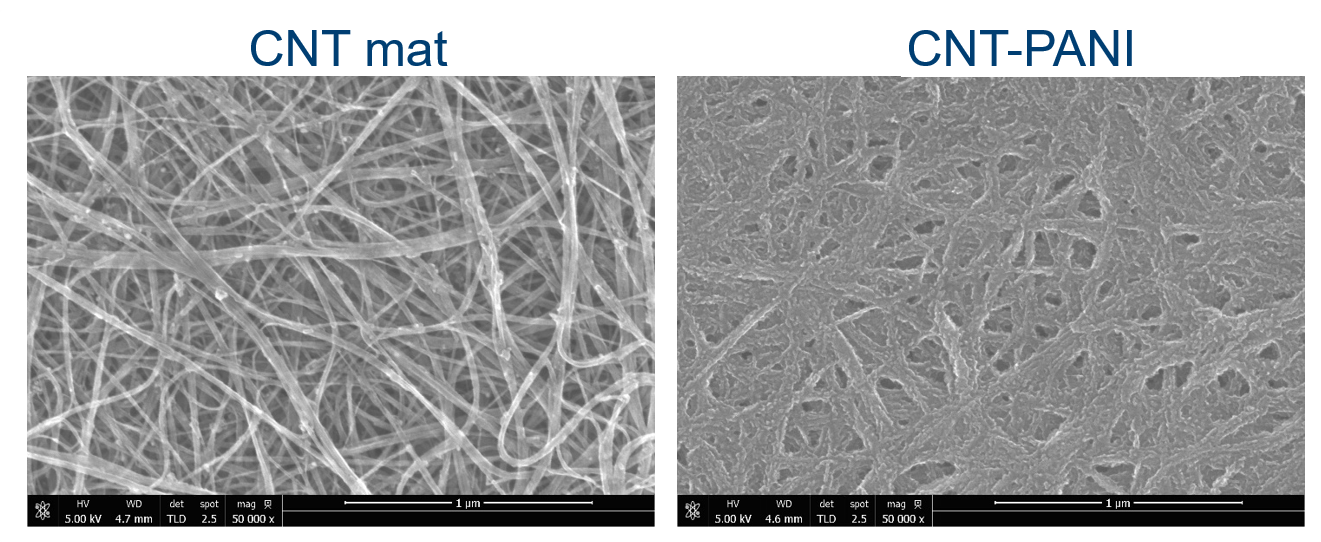

(4) Mechanics of direct-spun carbon nanotube mat and composites

Research summary:

CNT with superior structural, electrical and thermal properties, is of great potential to introduce multi-functionalities to CFPR, such as impact-tolerance, lightning strike protection and de-icing. Cambridge University has first proposed floating catalyst chemical vapour deposition method (FFCVD) to produce macroscopic CNT fibres/mats continuously in large volume (500 m2/day). However, the properties of macroscopic CNT fibres/mats haven’t yet reached the full potential of individual CNT (only 1% at present). To understand the properties of macroscopic CNT sheet, I have developed various novel characterisation and computational methods.

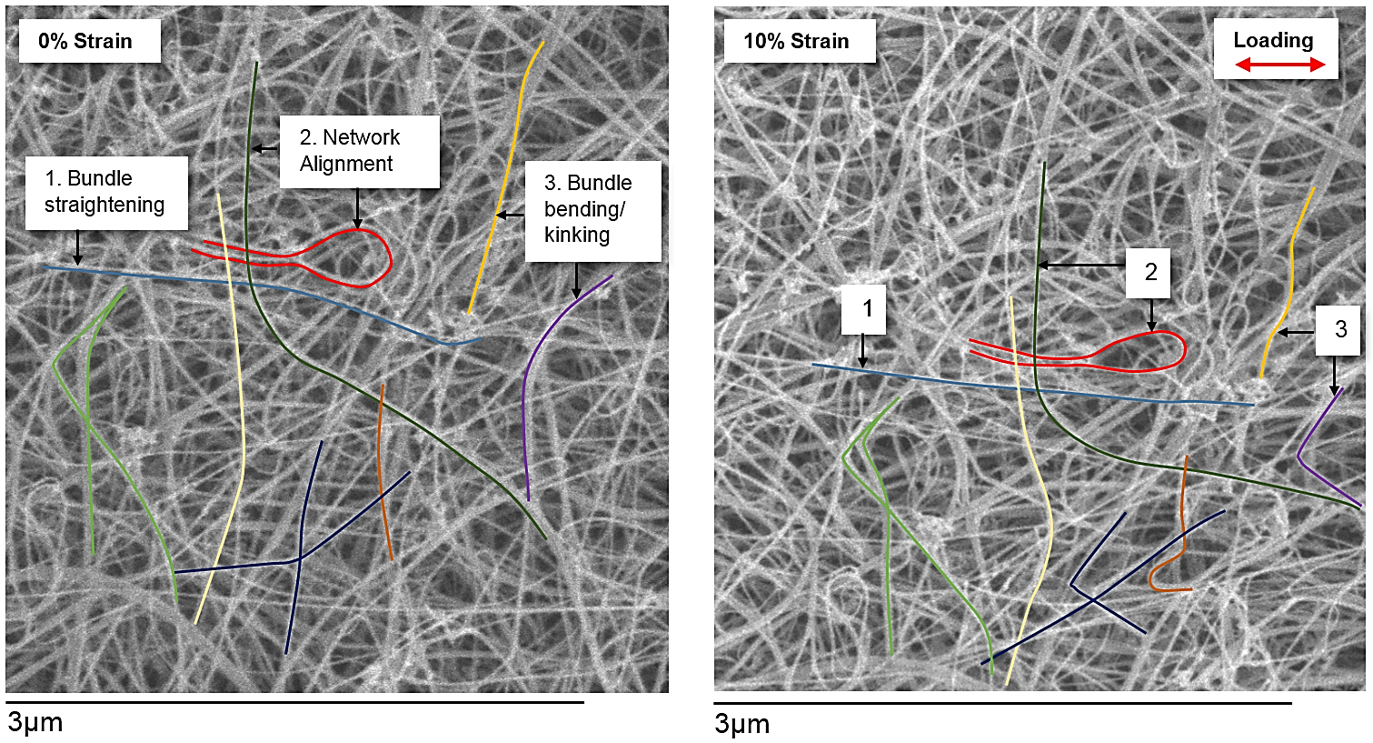

1) Achieved the first in-situ microscopy that reveals the deformation mechanisms of CNT mat. We found that CNT bundles form random interlinked bundle networks and the network deforms like a foam under tension, with dominant transverse deflection of struts. The lack of stretching on CNT bundles limits the macroscopic mechanical properties of CNT mat.

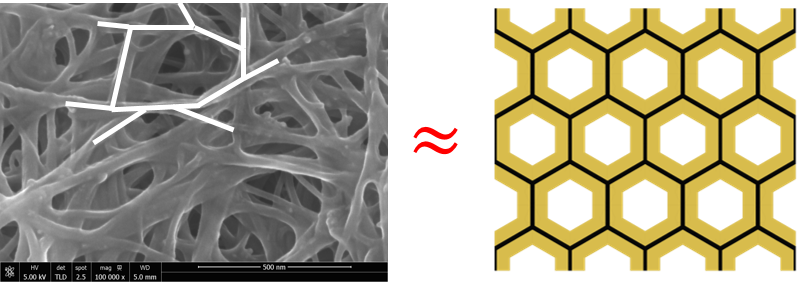

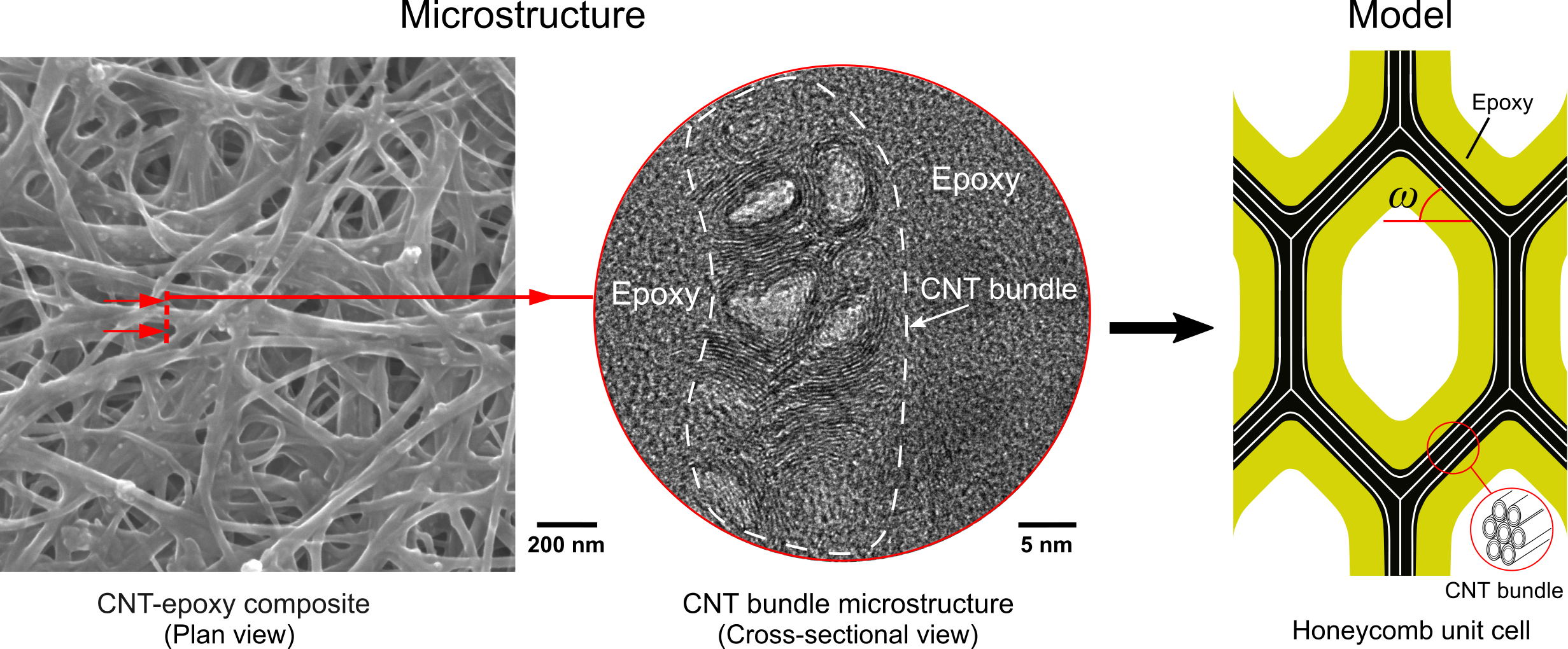

2) Elemental mapping of CNT-epoxy composite firstly revealed that epoxy resin does not penetrate CNT bundle. Consequently, the interfacial properties between individual CNTs are not improved. This explains the limitation of epoxy in the enhancement of CNT performance.

3) Proposed a novel micromechanical model to relate macroscopic CNT mat properties to those of CNT bundle network and CNT-epoxy composites. The model was able to describe the degree of elastic and plastic anisotropy of the composite and the dependence of modulus and yield strength upon composition. I also developed a special four-point probe system to measure the electrical conductivity of CNT-epoxy composites, eliminating the contact and wire resistance. A novel steady-state method using an infrared camera to measure thermal conductivity of CNT-epoxy composite under vacuum was also presented. These results found that the electrical and thermal conductivities of CNT-epoxy composite is primarily dependent on the CNT volume fraction.

References:

- Gspann TS, Kaniyoor A, Tan W, Kloza PA, Bulmer JS, Mizen J, Divitini G, Terrones J, Tune D, Cook JD, Smail FR and Elliott JA (2021). “Catalyst-Mediated Enhancement of Carbon Nanotube Textiles by Laser Irradiation: Nanoparticle Sweating and Bundle Alignment.” Mdpi Ag Catalysts vol. 11, (3) 368-368. DOI10.3390/catal11030368

- Tan W, Stallard JC, Smail FR, Boies AM and Fleck NA (2019). “The mechanical and electrical properties of direct-spun carbon nanotube mat-epoxy composites.” Carbon vol. 150, 489-504. DOI10.1016/j.carbon.2019.04.118

- Stallard JC, Tan W, Smail FR, Gspann TS, Boies AM and Fleck NA (2018). “The mechanical and electrical properties of direct-spun carbon nanotube mats.” Extreme Mechanics Letters vol. 21, 65-75. DOI10.1016/j.eml.2018.03.003

01-05-2018

Example: Mass production of direct-spun carbon nanotube mat (Tortech)

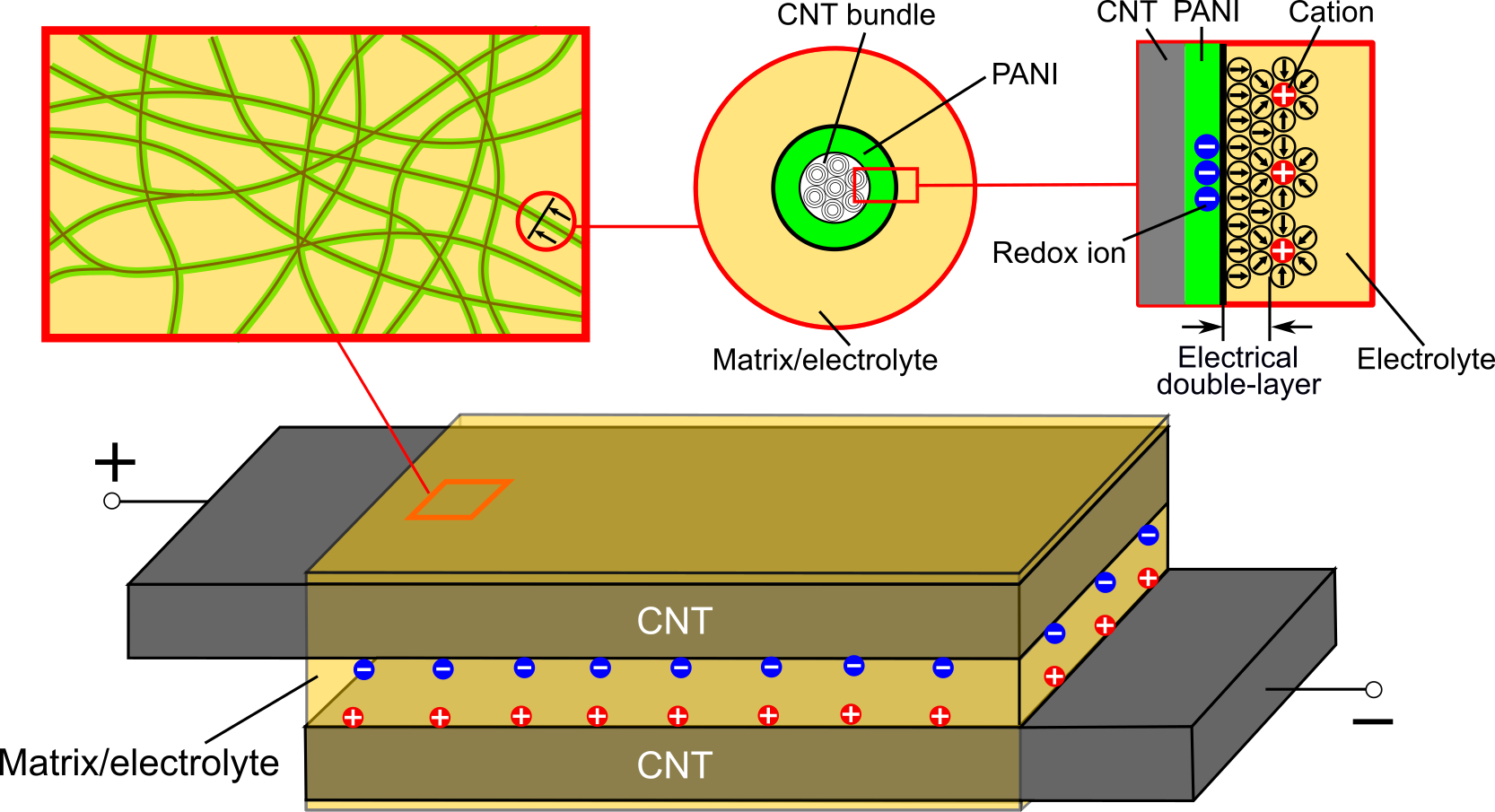

(5) Mechanics of materials for energy storage

Research Summary:

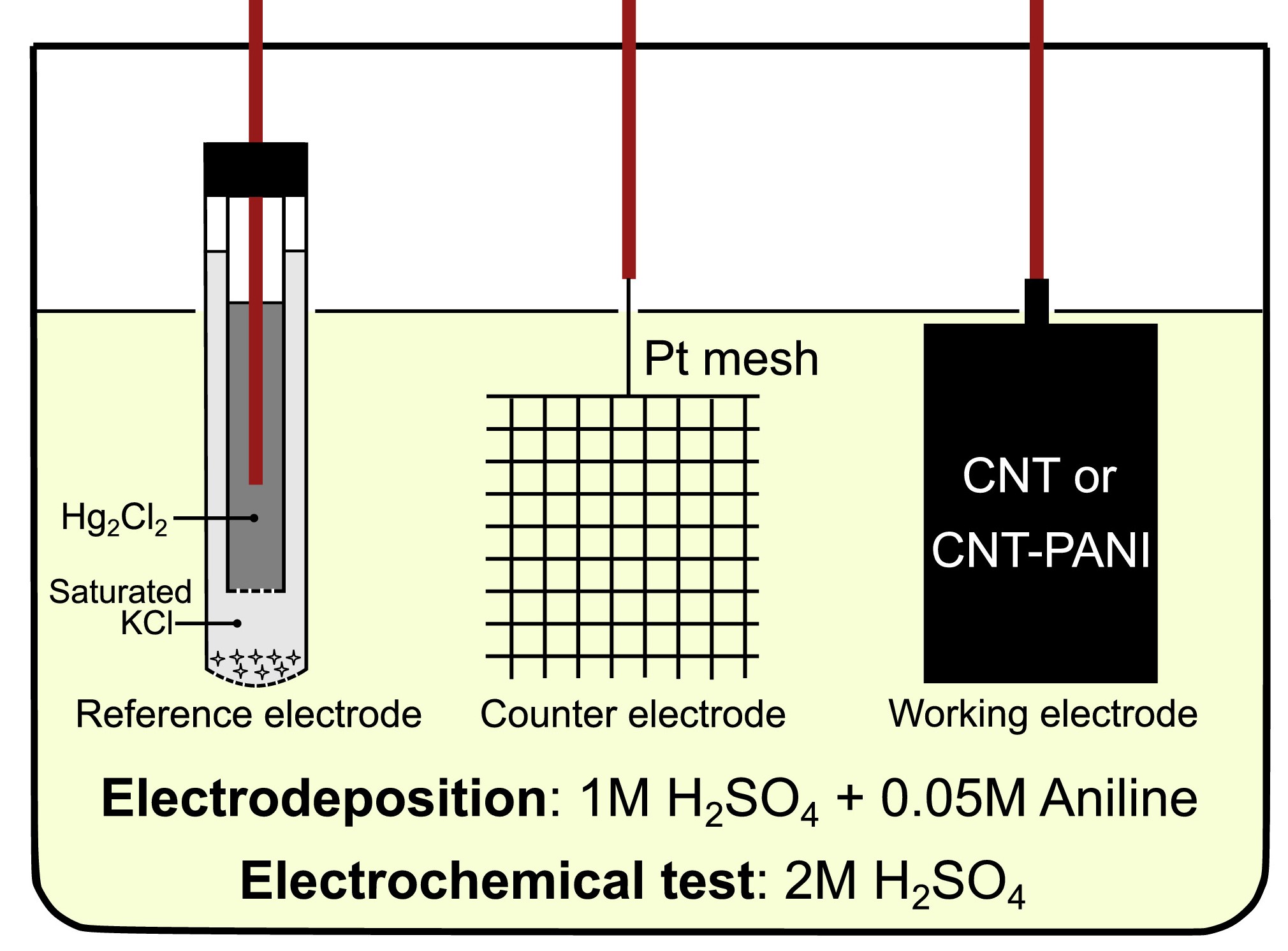

Novel direct-spun carbon nanotube–polyaniline composite electrodes have been developed for supercapacitor applications, offering high specific power and excellent cyclic stability for short-term energy storage, such as regenerative braking systems. Despite their technological relevance, the coupled electrochemical and mechanical behaviour of these electrodes remains insufficiently understood. In particular, the influence of charge–discharge rate, electrode composition, and state of charge on their electrochemical performance, mechanical integrity, and degradation under cycling and pre-charging is still unclear. These knowledge gaps limit the rational design of durable, high-power supercapacitor electrodes.

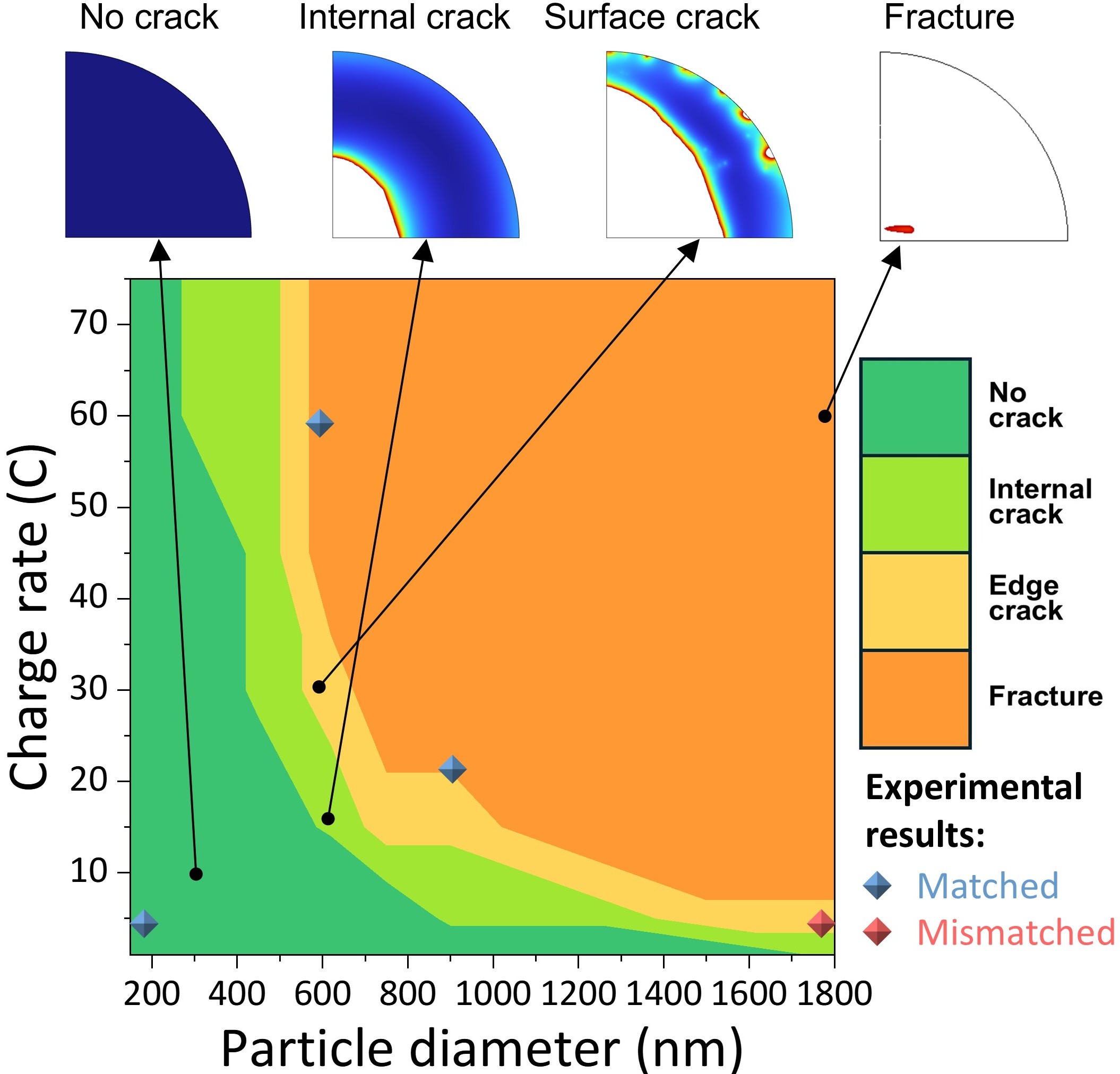

In parallel, recent advances in lithium-ion battery research have demonstrated the power of multiphysics modelling to uncover electrochemically driven degradation mechanisms at the material scale. For silicon-based anodes, a fully coupled framework integrating mass transport, deformation, phase-field fracture, and fatigue damage has been developed to investigate cracking and fracture during single lithiation–delithiation cycles and fatigue accumulation over repeated cycling. Systematic analyses revealed that higher charge rates, larger particle sizes, and pre-existing defects significantly accelerate cracking and reduce cyclic life, while the introduction of nanopores can mitigate fracture by reducing volumetric expansion, redistributing tensile stresses, and elongating crack paths.

Together, these studies highlight a common challenge across electrochemical energy storage technologies: the need to understand and predict degradation arising from strong stress–diffusion coupling under aggressive charging conditions. While the materials and applications differ, the silicon anode framework provides transferable mechanistic insight and modelling strategies that can inform future studies on the durability and optimisation of CNT-based supercapacitor electrodes.

References:

- Yang, J. and Tan, W., 2026. Fully coupled multiphysics modelling of fracture behaviour in silicon particles during lithiation–delithiation using the phase-field method. Engineering with Computers, 42(1), p.7. https://doi.org/10.1007/s00366-025-02233-w

- Koliolios, E., Mills, D. G., Busfield, J. J., & Tan W*. (2021). The Nail Penetration Behaviour of Carbon Nanotube Composite Electrodes for Energy Storage. Frontiers in Materials, 429. https://doi.org/10.3389/fmats.2021.741541.

- Tan W, Stallard JC, Jo C, De Volder MFL and Fleck NA (2021). “The mechanical and electrochemical properties of polyaniline-coated carbon nanotube mat.” Journal of Energy Storage vol. 41, DOI10.1016/j.est.2021.102757

Example: RECHARGEABLE Supercapacitor Tram

(6) Data-driven or numerical optimisation of composite materials

Research summary:

The adoption of cellular structures for applications involving crash energy absorption are increasing due to their beneficial mechanical properties including low weight and high specific energy absorption. This project aims to integrate the data-driven approach and finite element modelling for designing energy-absorbing composite materials.

References:

- Khosroshahi Siamak, Hirak, K., Miguel, B. & Tan, W. Data-driven framework for topology optimisation of energy absorbers. in European Solid Mechanics Conference 2022 (2022).

- Kansara, H. et al. Data-driven modelling of scalable spinodoid structures for energy absorption. in UK Association for Computational Mechanics (UKACM) conference 2021 (2021).

Research Projects (as PI)

- LSIMPACT: Life-like Resilient Materials for Mitigating Liquid-Solid Impact Damage,

ERC Starting Grant/UKRI Frontier Research, £1.3m, EP/Y037103/1, Aug. 2024-Aug.

2029, EU/UK.

This project develops self-healing and recyclable polymer materials inspired by

biological resilience to mitigate impact-induced damage, enabling extended service

life, reduced maintenance, and lower embodied CO2 in energy and transport appli-

cations. - CELLCOMP: Data-driven Mechanistic Modelling of Scalable Cellular Composites for

Crash Energy Absorption, EPSRC New Investigator Award, Grant NO. EP/V049259/1,

2022-2025, £392k, UK.

This project combines mechanics-based modelling and AI to design lightweight,

material-efficient cellular composites, enabling improved crash performance with

reduced material use and embodied CO2 for sustainable transport applications. - From Lab to Field: Developing Resilient Coating Materials for Rain Erosion Protection

in Wind Turbine Applications, funded by Henry Royce Institute/EPSRC, Royce Indus-

trial Collaboration Programme, Grant NO. EP/X527257/1, 2025-2026, £100K, UK.

The project is collaborating with Energy Technology Centre Ltd and the UK National X-

ray CT Facility to validate material performance under industry-relevant service con-

ditions, bridging laboratory-scale development with field testing. - Decoding the Material Degradation Mechanisms Under High-velocity Liquid-solid

Impact Loadings, Royal Society Research Grant, Grant NO. RGS/R1/231417, 2023-

2025, £70k, UK.

This project elucidates impact-driven degradation mechanisms in engineering mate-

rials to enable durable and erosion-resistant surfaces, supporting lifetime exten-

sion, reduced maintenance, and lower material and energy demand in energy and

infrastructure systems. - Structural supercapacitors using hybrid carbon fibre/carbon nanotube composites,

funded by University of Cambridge, CAPE Blue Sky Research Award, Grant NO.

NMZD/256, 2017-2018, £20k, UK.

This project explored multifunctional composite materials that integrate struc-

tural load-bearing and energy storage, enabling material efficiency, system level

lightweighting, and reduced component redundancy for sustainable energy and trans-

port applications.

Research Sponsors