I am glad to share the developed computational codes during our research. Full codes are also available in the Github (https://github.com/MCM-QMUL). Please cite the corresponding paper(s) if you use any of these codes. Feel free to contact me if you have any questions.

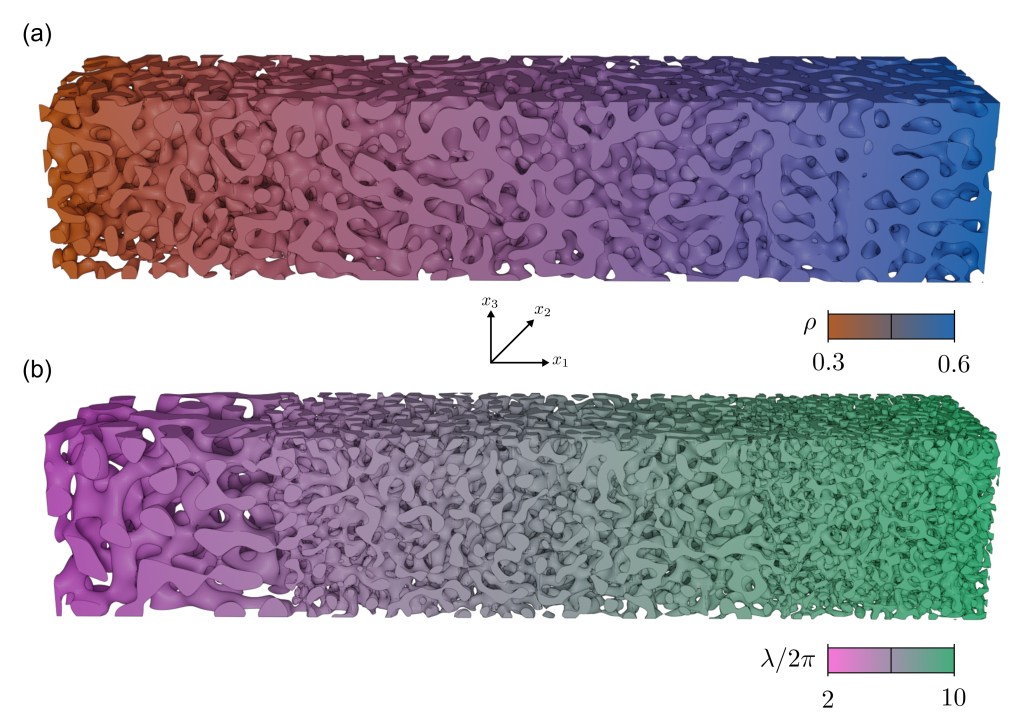

1. Multi-objective Bayesian Optimisation of Spinodoid Cellular Materials

This repository introduces a multi-objective Bayesian optimisation (MOBO) framework for optimising spinodoid structures—scalable, non-periodic topologies with efficient stress distribution—to enhance crush energy absorption under impact. The framework addresses the challenge of balancing conflicting objectives: maximising energy absorption while minimising peak forces, accounting for non-linear material behavior and plastic deformation. By integrating finite element analysis (FEA) with Bayesian optimisation, it efficiently navigates the design space, reducing computational costs compared to conventional methods (e.g., NSGA-II). Key features include:

- Pareto-optimal solutions via scalarisation and hypervolume techniques.

- Avoidance of structural densification to maintain integrity.

- Superior performance over NSGA-II in computational efficiency and solution quality.

Ideal for real-world structural/material optimisation where complex trade-offs and non-linear dynamics are critical. Click the link to download: Github repository. Please contact me if you have any questions (wei.tan@qmul.ac.uk).

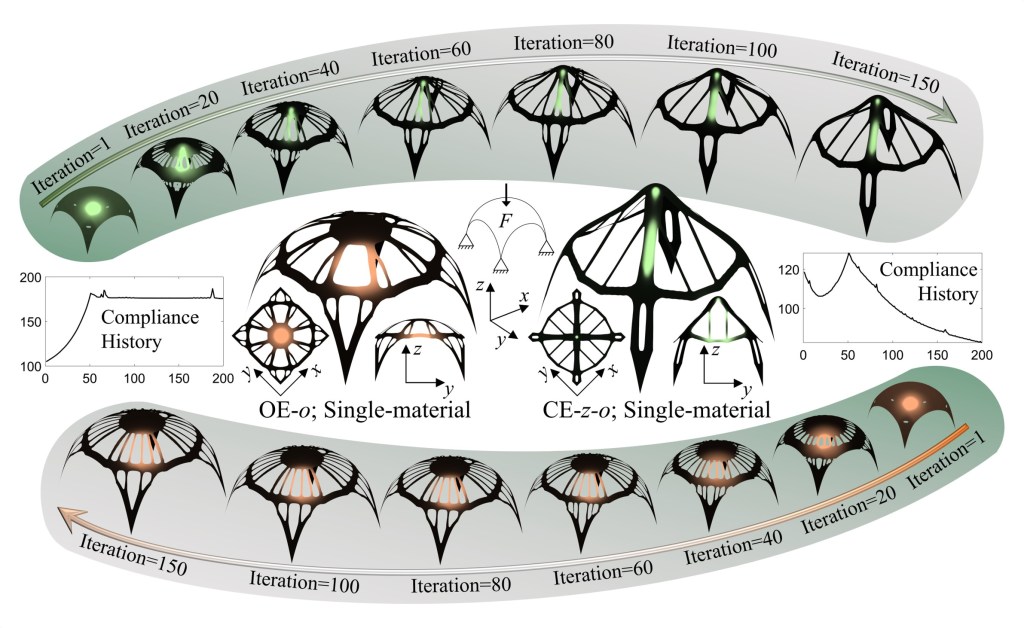

2. Co-design of Structures via Generalized Evolution

The framework enables simultaneous shape and topology optimisation by evolving two surrogate hypersurfaces through tangential (shape) and orthogonal (topology) evolution. A quasi-conformal transformation ensures compatibility, and an ALE method maintains mesh quality during structural evolution.

The method offers a unified mathematical framework for simultaneous shape and topology optimisation by evolving two surrogate hypersurfaces via tangential (shape) and orthogonal (topology) motions. A quasi-conformal transformation ensures consistent geometry updates, while an ALE strategy preserves mesh quality during evolution.

Click the link to download: Github repository. Please contact me if you have any questions (wei.tan@qmul.ac.uk).

[1] Liu, Y., Xia, B., Li, Z., Ren, H., Du, J., Tan, W. (2025). Co-design of structures via generalized evolution. Computer Methods in Applied Mechanics and Engineering, 118584. https://doi.org/10.1016/j.cma.2025.118584

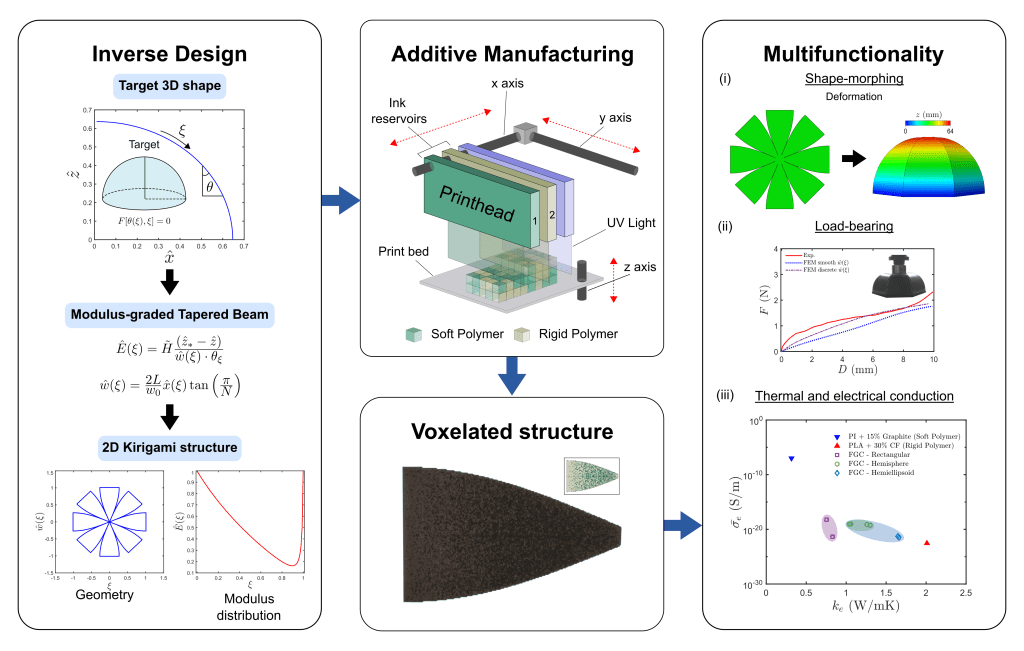

3. Inverse Design Framework for Shape Morphing Composite Materials

Shape-morphing structures can transform from flat 2D sheets into complex 3D forms, offering broad application potential. This work presents a novel inverse design framework that achieves controlled morphing by tailoring spatial variations in bending stiffness through modulus-graded functionally graded composites (FGCs), rather than geometric cuts. Using nonlinear beam theory, the required modulus distribution is determined to realise prescribed axisymmetric 3D shapes. The structures are fabricated via multi-material 3D printing with voxel-based grading, enabling precise control of local stiffness through micromechanical mixture rules. Numerical and experimental results demonstrate excellent agreement across a wide range of morphologies and Gaussian curvatures. The framework further reveals multifunctionality, showing that modulus-graded morphing structures can combine distinct mechanical, thermal, and electrical properties within a single architecture, enabling adaptable performance in multi-physical environments.

Click the link to download: Github repository. Please contact me if you have any questions (wei.tan@qmul.ac.uk) or Dr Mingchao Liu (m.liu.2@bham.ac.uk)

[1] Kansara, H., Liu, M. * , He, Y., Tan, W. * (2023). Inverse design and additive manufacturing of shape-morphing structures based on functionally graded composites. J Mech. Phys. Solids, 105382.

4. Phase field fracture models

A computational framework to explore the effect of microstructure and constituent properties upon the fracture toughness of fibre-reinforced polymer composites is presented. A phase field fracture method and a cohesive zone model are coupled to capture microscopic matrix cracking and fibre-matrix debonding. This model is possible to accurately capture the crack path, interface debonding and load versus displacement response. The sensitivity of the crack growth resistance curve (R-curve) to the matrix fracture toughness and the fibre-matrix interface properties is determined. The influence of porosity upon the R-curve of fibre-reinforced composites is also explored, revealing a higher crack growth resistance with increasing void volume fraction. These results shed light into microscopic fracture mechanisms and set the basis for efficient design of high fracture toughness composites.

Click the link to download: Codes link or Github repository. Please contact me if you have any questions (wei.tan@qmul.ac.uk) or Dr. Emilio Martinez-Paneda (e.martinez-paneda@imperial.ac.uk)

Reference:

[1] W. Tan, B.G. Falzon, L.N.S. Chiu, M. Price, Predicting low velocity impact damage and Compression-After-Impact (CAI) behaviour of composite laminates, Compos. Part A 71 (2015) 212-226.

[2] W. Tan, and E. Martinez-Paneda, Phase field predictions of microscopic fracture and R-curve behaviour of fibre-reinforced composites. Compos. Sci. Technol. 2021.

5. Strain-rate dependent crystal plasticity model for composite laminates

By analogy, we developed a micromechanical model to capture the matrix shearing and fibre rotation of CFRP under finite strain and different strain rates, inspired by the crystal plasticity theory. Strain rate dependency of the shear modulus and yield strength of matrix is modelled through scaling functions [3]. We then validate the predictive capabilities of this micromechanical model against the measured stress-strain responses of unidirectional (UD) and cross-ply composite laminates.

Click the link to download: Codes link. Please contact me if you are interested (wei.tan@qmul.ac.uk) or Dr Liu. B (bl377@eng.cam.ac.uk).

References:

[3] Tan, W. and Liu, B., 2020. A physically-based constitutive model for the shear-dominated response and strain rate effect of Carbon Fibre Reinforced composites. Composites Part B: Engineering, p.108032.

6. Continuum damage model

Throughout the years, we have developed a continuum damage model [4] to model the nonlinear behaviour of fibre-reinforced composite, considering fibre and matrix damage. This model was used to predict both low-velocity impact damage and CAI strength of composite laminates, has been developed and implemented as a user material subroutine in the commercial finite element package, ABAQUS/Explicit.

Click the link to download: Codes link. Please contact me if you have any questions (wei.tan@qmul.ac.uk) or Prof. Brian Falzon (brian.falzon@rmit.edu.au)

Reference:

[4] W. Tan, B.G. Falzon, L.N.S. Chiu, M. Price, Predicting low velocity impact damage and Compression-After-Impact (CAI) behaviour of composite laminates, Compos. Part A 71 (2015) 212-226. (JCR Q1, IF:6.28, Citations: 280+).

7. Cohesive zone model

Cohesive elements are commonly used in modelling adhesives, bonded interfaces, composite laminates. The constitutive response of these elements usually assume a traction-separation law of the interface. Just like assuming the cohesive element as a linear-elastic spring. It will be able to pick up loading in mode I (open) and mode II (shear). Damage initiates when the assumed criteria is reached (e.g. Maximum stress, Quadratic nominal stress criterion). The damage evolution will be governed by a defined fracture toughness value (e.g. critical energy release rate Gc).

Click the link to download: Code link: Please contact me for more questions (wei.tan@qmul.ac.uk)

Reference:

[2] W. Tan, and E. Martinez-Paneda, Phase field predictions of microscopic fracture and R-curve behaviour of fibre-reinforced composites. Compos. Sci. Technol. 2021.